Environmentally Friendly

Production

Rosenbauer is taking responsibility in production. Thus the company is relying on green electricity and a reduction in energy, water and waste.

ENERGY AND RESOURCE EFFICIENCY

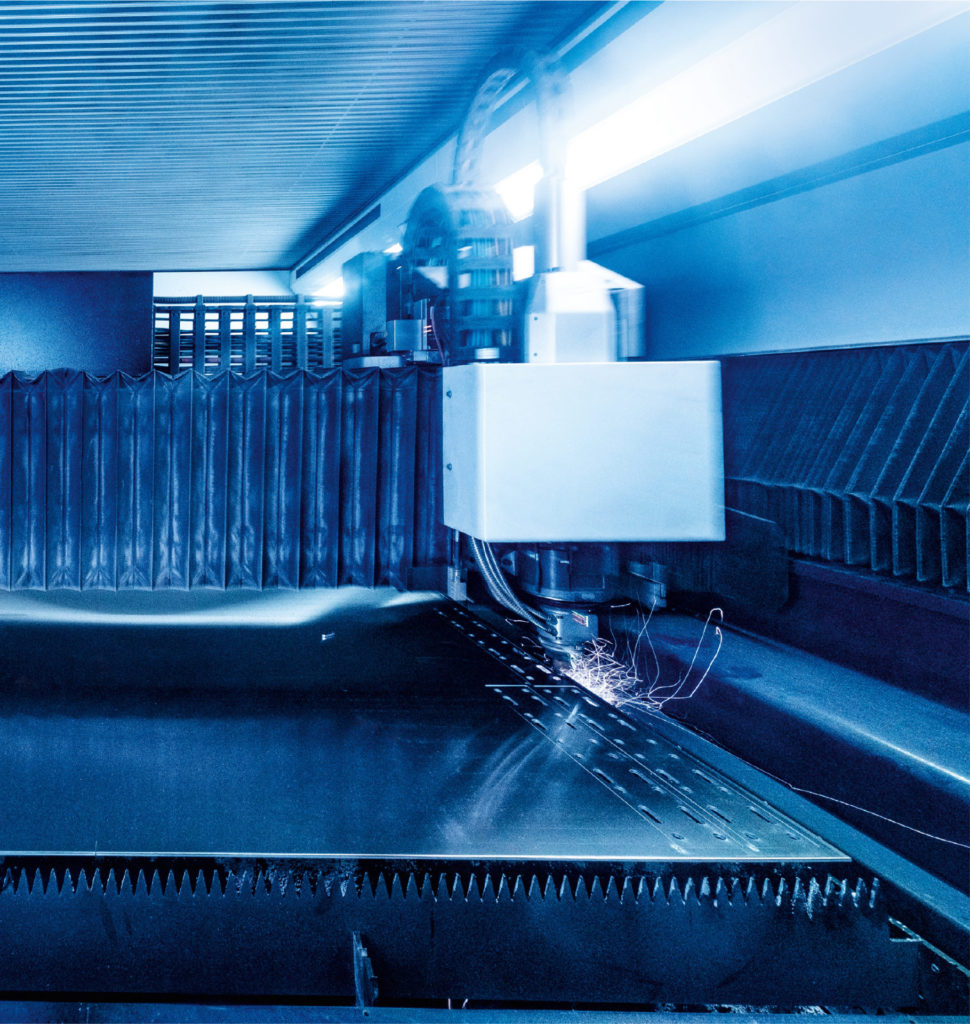

Rosenbauer’s production activities primarily involve machinery and specialty vehicle assembly, and/or metal and plastics processing. It is a priority for Rosenbauer to take action in these areas, particularly in the material topics of Energy efficiency and reduction of greenhouse gas emissions and Resource consumption in production.

Responsibility for these issues lies with Production managers. There are dedicated environmental managers at the individual Production locations who monitor energy and water usage, waste and other environmental matters. Rosenbauer structures management of these issues with an environmental management system certified to ISO 14001 and an ISO 50001-compliant energy management system at some locations. The existing goals and measures are evaluated at regular intervals.

ENERGY EFFICIENCY AND REDUCTION OF GREENHOUSE GAS EMISSIONS

To continuously optimize its energy footprint, Rosenbauer analyzes and estimates all relevant workflows, machinery, buildings, and processes according to their energy efficiency and develops corresponding measures to increase it.

Total Energy Consumption The Rosenbauer Group’s energy requirement in the reporting year totaled 62,980.6 MWh (19 kWh per productive hour) and therefore decreased slightly in relation to 2019. Generally, production sites with paint shops use the most process and heating energy. Sales, assembly, and customer service operations account for most of our fuel consumption. Locations where the buildings and factory spaces require yearround cooling consume relatively high levels of electricity.

Renewable sources supply energy, 65.9% of the electrical while 6.9% of that is from the in-house cogeneration plant in Leonding and the photovoltaic systems in Mogendorf, Neidling and Leonding. District heating, which is largely generated from waste heat, in turn provides 24.6% of the process and heating energy used. Diesel accounts for 90.9% of the fuel used.

Climate Action and Reduction of Greenhouse Gas Emissions

To reduce its overall energy consumption, Rosenbauer uses waste heat from production to heat its paint shops. These facilities are continually modernized. Leonding plant I in turn uses the waste heat from the paint shop to heat the office buildings. Leonding plant II has used district heating since 2016, and Leonding plant I was connected to district heating in 2020. The Karlsruhe location has also been heated with district heating since 2016.

All renovations and conversions include thermal insulation for buildings and factory spaces, and offices are equipped with modern daylight and heating controls. LED lighting is gradually being introduced in factory spaces, and energy-saving tools such as speed-controlled air compressors with consumption control are used as well. When the Radgona, Slovenia, location was retrofitted, heat exchangers were installed to blow warm air near factory ceilings back downward, thereby considerably reducing the need for heating. Efficient production logistics with just-in-sequence supply also cuts carbon emissions.

In Production, the majority of our European firefighting vehicles are already built on chassis with a Euro 6 drivetrain, which means their NOX and particulate emissions are respectively around 80% and 66% lower than those of Euro 5 vehicles.

Rosenbauer has set itself the goal of drawing up a comprehensive climate strategy based on the requirements of the Science Based Targets Initiative in 2022. To this end, it is necessary to analyze current greenhouse gas emissions and identify reduction potential. In addition, the company also wants to address emissions from the value chain, so-called Scope 3 emissions. In order to increase the transparency of its climate commitment to stakeholders, Rosenbauer reported to CDP Climate Change for the first time in 2021 and achieved a rating of “C” (Awareness level). The feedback and suggestions from this year’s rating will be incorporated into the next reporting process as part of an iterative development and derivation of measures. Rosenbauer is aiming for the top rating of “A” (Leadership Level) by 2025.

| Greenhouse gas emissions of Rosenbauer Group (in t CO2eq)* | Market-based | Country-based | ||||

|---|---|---|---|---|---|---|

| 2021 | 2020 | 2019 | 2021 | 2020 | 2019 | |

| Total Scope 1 + Scope 2 | 11,861 | 14,003 | 15,951 | 14,761 | 17,335 | 19,017 |

| Direct greenhouse gas emissions (Scope 1) | 7,210 | 8,776 | 10,260 | 7,210 | 8,776 | 10,260 |

| Indirect energy-related emissions (Scope 2 resulting from the use of district heating and electricity) | 4,652 | 5,227 | 5,691 | 7,552 | 8,559 | 8,758 |

| Energy consumption of Rosenbauer Group | 2021 | 2020 | 2019 |

|---|---|---|---|

| Total* | |||

| MWh | 59,705.5 | 62,980.6 | 67,485.1 |

| kWh per prod. hour | 18.2 | 19.0 | 19.3 |

Electricity |

|||

| MWh | 16,570.0 | 16,011.2 | 16,530.0 |

| kWh per prod. hour | 5.0 | 4.8 | 4.7 |

Heating |

|||

| MWh | 28,325.0 | 31,310.1 | 34,099.3 |

| kWh per prod. hour | 8.6 | 9.5 | 9.8 |

Fuels |

|||

| MWh | 14,809.0 | 15,659.3 | 16,855.9 |

| kWh per prod. hour | 4.5 | 4.7 | 4.8 |

* Sources of conversion factors: Austrian Federal Ministry for Agriculture, Regions and Tourism (Energy Efficiency Act) and Austrian Federal Environmental Agency (GEMIS 4.94)

Increase in Green Electricity and Electricity Generated by the Company

The share of green electricity fell to 64.8% compared with the previous year due to increased electricity consumption at locations with a low share of renewable electricity. The target of meeting 75% of electricity demand from renewable energy sources by 2021 was thus missed and is now to be achieved by 2025. The large production locations in Austria and Germany have been operated using 100% green electricity since 2019.

The target of covering 5% of total electricity requirements with photovoltaic systems by 2021 was not achieved. The target value includes both self-generated energy and electricity from systems on rooftops that are rented by Rosenbauer. The output of the existing photovoltaic systems at the Leonding and Neidling locations covers 4.1% of the Group’s total electricity requirements. Following a relocation, the Mogendorf location no longer has a photovoltaic system. It is planned to check further sites for their suitability for photovoltaic systems in the coming years.

Status Goal Share of green electricity

Employee mobility

Rosenbauer’s commitment to the environment includes providing alternative and sustainable forms of transportation for employees. As early as 2019, the Carployee ride sharing app was introduced at the locations in Upper Austria. This enables employees to ride together to and from work, thereby saving money. And it is an environmentally friendly way to commute. Rosenbauer promotes this initiative by providing benefits to active users. Since the project’s introduction, employees have traveled more than 1,700,000 km fewer on the roads, which corresponds to around 232 metric tons of carbon emissions. The development of users in 2021 shows an increase of almost 11% compared to the previous year. As in 2020, lower user activity was observed especially during the lockdown phases of the COVID-19 pandemic.

RESOURCE CONSUMPTION IN PRODUCTION

As a producer of firefighting vehicles, Rosenbauer needs aluminum and steel as primary raw materials. Both materials are easy to recycle but manufacturing them consumes a great deal of energy. Rosenbauer minimizes surface treatments so that the materials can be recycled as far as possible without slags. Other important raw materials come from the plastics industry. Chassis and manufacturing material make up the largest share of the Group’s procurement volumes. Rosenbauer buys almost exclusively prefabricated, mostly ready-to-install parts: for vehicle superstructures these are primarily aluminum sandwich panels, aluminum sheets and profiles, and for vehicle trims and design fairings, preformed parts made of plastic, the raw materials for which are often precolored by the supplier in the vehicle color. Aluminum, stainless steel or gunmetal housing is used for firefighting pumps. The pump shaft and other pump units are procured as steel blanks and finished in-house.

Rosenbauer supplies a wide range of extinguishing systems as well as high and ultra-high pressure pumps for efficient extinguishing with less water. Considerable amounts of water are used over the course of numerous quality tests during the manufacture of firefighting pumps. For this reason, one of Rosenbauer’s chief concerns is to ensure the careful use of this resource, for instance by refurbishing pump test stands to make resource use more efficient.

In 2018, Rosenbauer began using only non-water-based paints free of heavy metals in production. This both reduces environmental pollution and preserves employee health.

Total water consumption in production

Leonding plant I has the highest water requirement of any location in the Group. This is where Rosenbauer produces all pumps and extinguishing systems that must be tested with water as part of quality assurance. Water is also required for vehicle deliveries to demonstrate the extinguishing functions for customers. This is the case at most Rosenbauer production locations worldwide. On the pump test stands, where every unit from the smallest portable pump to the highest-volume truck-mounted fire pump is subject to a one-hour endurance test, the required water is recirculated. Depending on the pump capacity, this saves between 30 and 780 m³ of fresh water in each test cycle. Since around 3,000 units are tested per year, this saves an enormous volume of water.

The water used by Rosenbauer contains only very minimal contaminants. At all locations, waste water is of sufficient quality and is therefore released into the public sewer system. In addition, water purification facilities, such as mineral oil separators, are installed at several locations. This keeps the environmental impact of waste water as low as possible.

The availability of water in a region depends on the available water resources on the one hand and on the amount of water extracted on the other hand. If the volume extracted exceeds a certain percentage of the resources available, this is defined as water stress. Good stewardship of water as a resource is particularly important in regions experiencing water stress. Use of the WWF Water Risk Filter determined that Rosenbauer’s plants in Saudi Arabia, Spain, Wyoming (Minnesota, USA), Luckenwalde (Germany), and Moscow (Russia) are located in regions experiencing water stress. In the future, additional measures will be taken to further reduce water consumption at these locations and to raise awareness among employees of this issue.

The helmet production line in Linz, Austria, manufactured 87,000 helmets last year

In the reporting period, the Rosenbauer Group’s total water consumption amounted to 80.931,5 m3, which is equal to specific water consumption of 24.6 liters per productive hour. 39.7% of the water consumed came from Rosenbauer’s own wells, the rest from the municipal supply. Compared with the previous year, total water consumption decreased by around 4%.

| Water consumption of Rosenbauer Group (m3) | 2021 | 2020 | 2019 |

|---|---|---|---|

| Municipal | 48,822.5 | 45,060.1 | 42,944.9 |

| thereof in water-stressed areas | 19,7% | 19,5% | 25,9% |

| Liters per prod. hour | 14,9 | 13.6 | 12.3 |

| Well water | 32,109.0 | 39.437,0 | 47,341.0 |

| thereof in water-stressed areas | 3.4% | 3.4% | 2.7% |

| Liters per prod. hour | 9.8 | 11.9 | 13.5 |

| Total* | 80,931.5 | 84,497.1 | 90,285.9 |

| thereof in water-stressed areas | 13.5% | 12.0% | 13.8% |

| Liters per prod. hour | 24.6 | 25.5 | 25.8 |

New test stand for high-performance pumps

The original Leonding plant has three pump test stands. Only one of these is designed to test larger pumps and pumping systems. This was rebuilt in 2020. Now the units’ drive systems are tested using an environmentally friendly and quiet electric motor, as in the case of the other pump test stands. A number of steps were taken to increase safety for the testing team and to make the testing process more efficient. For instance, high-performance monitors were installed to display power usage and issue an automatic warning when it gets too high. If this happens, the power drawn is automatically limited or the output is no longer increased. This helps to avoid expensive peak current. The water for the pump tests is pulled from a supply tank, routed through a separate catch basin and then put into circulation.

The largest water consumption in production occurs during the functional test of the turret

Reduction of plastic used in helmet production

Rosenbauer has already been conserving 100,000 m² of plastic film each year since 2019 by switching to reusable packaging in helmet production. In addition, most of the helmet shells are now painted by robots. This also reduces “overspray”, or the paint that misses the helmet and must be disposed of.

Scrap plastic parts are collected at Rosenbauer and taken to a recycling partner, who uses them to produce new plastic granulate.

Reduction of noise emissions in production

An important stakeholder group for Rosenbauer is the neighbors living around the production facilities. To protect them from noise, new buildings and conversions are equipped with noise barriers, and noisy tests are performed in enclosed, soundproofed factory spaces. At production locations with direct neighbors, it is determined systematically how and to what extent they are disturbed by noise at Rosenbauer. There were no complaints in the reporting year. Rosenbauer has maintained regular contact with neighbors in Leonding for decades.

Total volume of waste

The volume of waste produced by the Rosenbauer Group in 2020 was around 3,917 t (1.2 kg per productive hour). Around 6% of the waste was hazardous, such as paints, solvents, batteries and used oils. Residual waste for disposal accounted for 6% of the total. All other used materials and waste were recycled. Specifically, this included aluminum, steel, recyclable plastics and cable residues, wood, glass, cardboard and paper. The figures are partly based on estimates, as not all locations keep detailed records. For waste disposal, Rosenbauer recycles as a matter of course and relies on local conditions and suppliers at all locations.

Waste collection islands are distributed over the entire site at every location and enable accurate separation of the waste and residual materials accumulating in each area. Final disposal is carried out by authorized specialists. Regular training is conducted to promote and increase awareness among employees. The motto here is “avoidance before separation, separation before recycling, recycling before disposal”. A specific measure implemented at the service location in France and a production location in Germany, for example, was replacing disposable cloths for cleaning oil residue with reusable cloths washed by a cleaning service.

| Waste of Rosenbauer Group | 2021 | 2020 | 2019 |

|---|---|---|---|

| Total* | |||

| t | 3,660 | 3,917.1 | 3,450,0 |

| kg per prod. hour | 1.1 | 1.2 | 1.0 |

| t | 260.4 | 233.3 | 178.3 |

| kg per prod. hour | 0.1 | 0.1 | 0.1 |

| Recyclable waste* | |||

| t | 3,111.3 | 3,452.5 | 2,966,9 |

| kg per prod. hour | 1.0 | 1.0 | 0.9 |

| Residual waste | |||

| t | 288.9 | 231.3 | 304.8 |

| kg per prod. hour | 0.1 | 0.1 | 0.1 |

* Used material, non-hazardous waste without residual waste