The factory of the future

The virtual world has long since arrived at modern production facilities. Today, the entire value chain is digitally controlled, and communication largely takes place via platforms.

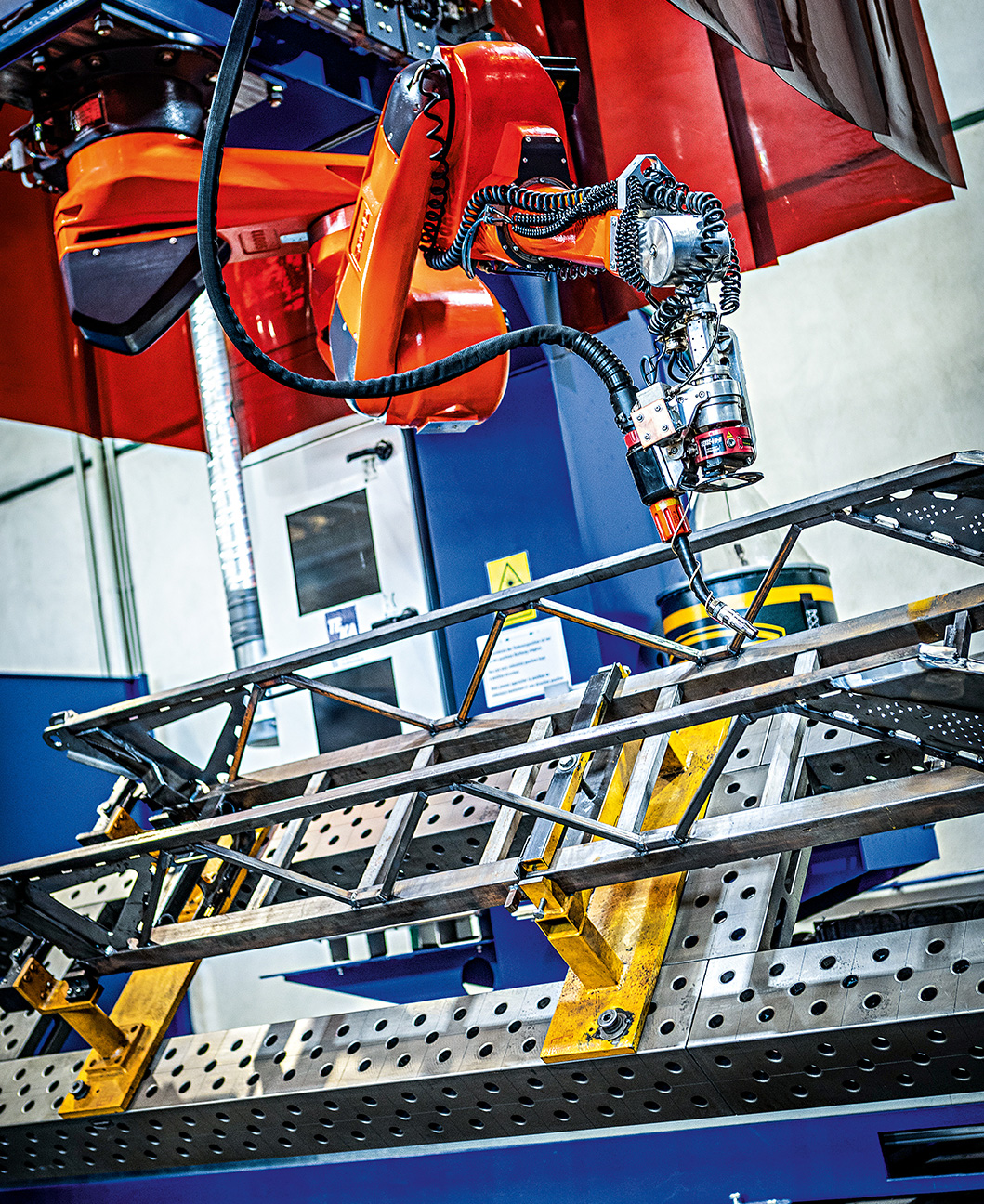

Data makes modern production run smoothly. This image shows the robot-assisted ladder production at the Karlsruhe location.

Precise components of the same quality form the prerequisite for harmonizing series, as Rosenbauer has done in the municipal vehicle sector in 2020.

Since products can be designed on computers and manufactured with the aid of computers, data has played a central role in industrial manufacturing. It forms the basis of production planning and supply chain management systems and, with today’s networking technology, allows the virtual mapping of entire value chains. Rosenbauer is thus able to digitally mirror its two main plants, Leonding I and II, and to plan, control, and monitor them on the virtual interface. “This gives us access to evaluations of our processes at any time, for example whether the real output of production corresponds to what we have input in the virtual world,” says Daniel Tomaschko, CTO of Rosenbauer. Trend developments and deviations, from production output to the availability of individual components, are thus available at a glance.

A further advantage of mirrored production is the ability to run simulations with operational data. In this way, individual work steps through to complex processes can be analyzed and optimized without having to interrupt production for this purpose. In addition, the data obtained in production is also used in product development, quality management and for the preventive service.

“Data creates facts and thus a factual basis for identifying potential, recognizing trends and being able to do what we set out to do better,” says Daniel Tomaschko.

»Data creates facts and brings decision-makers together at the factual level.«

Daniel Tomaschko, CTO

Networked suppliers

Supplier management at Rosenbauer is also organized digitally. All the players involved meet on an online platform through which inquiries and orders can be placed and processed automatically. Suppliers are directly integrated into the Rosenbauer planning matrix and receive all the necessary documents and information from the system in order to without having to interrupt production for this purpose. In addition, the data obtained in production is also used in product development, quality management and for the preventive service. “Data creates facts and thus a factual basis for identifying potential, recognizing trends and being able to do what we set out to do better,” says Daniel Tomaschko. DANIEL TOMASCHKO, CTO PRECISE COMPONENTS OF THE SAME QUALITY form the prerequisite for harmonizing series, as Rosenbauer has done in the municipal vehicle sector in 2020. supply production with their goods on a just-in-time basis. The portal is also used to evaluate and certify suppliers, monitor the quality of deliveries, and allow interested parties to offer their services.

Customer relationships are also managed on a digital platform. The complete quotation and order process is documented in Customer Relationship Management and can thus be traced by all authorized persons in the Rosenbauer organization. By continuously updating the data, a detailed overview is obtained over time, which is used to systematically shape customer relationships.

Programmed parts

In production, data represents one of the most important operating resources. It is created once in the course of engineering or order planning and then used throughout the entire production process: in the machine centers for the fully automated production of pump components, in the laser cutting plants for the high-precision series production of printed circuit boards, in the welding of complex pipe cross sections and in the robot-assisted production of extinguishing agent tanks, sprinkler pipes and aerial ladder superstructures. The robots at the Karlsruhe location, for example, work with around 1,500 data records when they produce the ladder set of a standard aerial ladder. Rosenbauer is thus the only manufacturer that has so far succeeded in digitalizing and robotically producing the ladder set.

4,2 MILLION EURO

Rosenbauer has invested € 4.2 million in robot production at the Karlsruhe location.

AUTOMATED TANK PRODUCTION

Precision through industrial production

The extinguishing agent tanks are cut to size by portal milling machines and welded by 9-axis robots.

GUARANTEED QUALITY

Digitalized production technology

Data from engineering flows directly into automated production.

INDUSTRY 4.0

Interfaces to the IT world

All production-relevant information is available on assembly cockpits.

FUTURE BOX

In September 2020, Rosenbauer opened a new production plant at the Karlsruhe location. It is the world’s first, robot-assisted production of ladder sets for aerial ladder vehicles. The almost complete digitalization of production has created a factory of the future.